15KW Practical Commercial Electromagnetic Induction Heating Control Board

¥735.00

Discount

[new_user_coupon_discount_and_code]

Technical Parameters

?

|

Rated power: |

15KW |

|

Rated voltage frequency: |

380V |

|

Voltage adaptation range: |

380V¡À20% |

|

Adapt to ambient temperature: |

-20~40?C |

|

Adapt to ambient humidity: |

¡Ü90% |

|

Power adjustment range: |

20~100% |

|

Thermal conversion efficiency: |

¡Ý90% |

|

Effective power: |

15KW |

|

Working frequency: |

5~40kHz |

Industry Use Induction Heater for Screw and Barrel

Features:

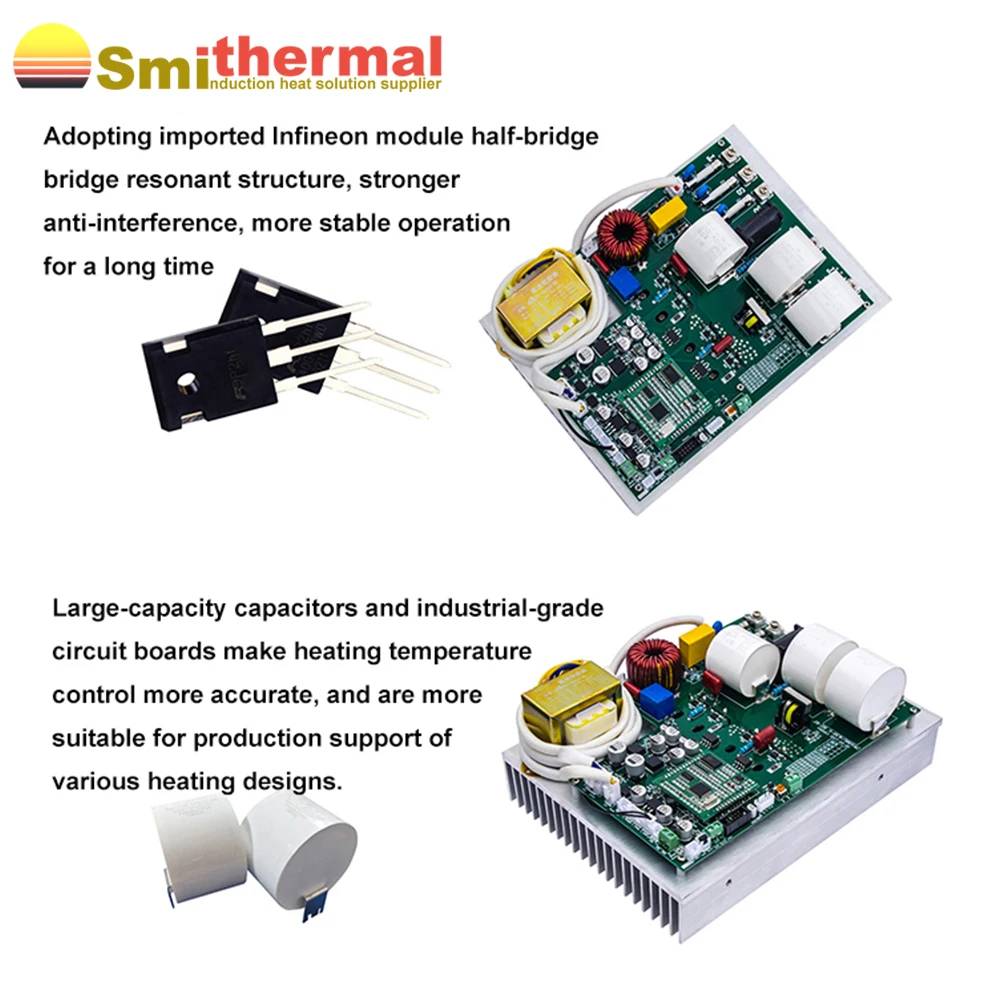

Three-phase 15KW digital electromagnetic heating control board with high-speed diaphragm drive and Infineon IGBT module. It has the characteristics of stable performance, low failure rate, long working life and remarkable energy saving effect. Support standard modbus RTU communication protocol. Can be widely used in plastic machinery (such as injection molding machine, wire drawing machine, granulator, extruder energy-saving renovation project) food machinery, crude oil transportation, heating and other similar heating industry.

Principle of electromagnetic heating:

Most of the metal is heated by the high-frequency magnetic field and uses this principle to pass the high-frequency current through the coil, so that the coil generates a high-frequency magnetic field, so that the metal rod in the coil is induced to generate heat.

The electrical energy can be converted into metal thermal energy by the above process. During the whole process, the metal rod does not have any physical contact with the coil, and the energy conversion is completed by the magnetic field eddy current and the metal induction.

Advantages of induction heating:

1/Energy saving and emission reduction (30-85%)

2/higher thermal efficiency

3/Reduced operating temperature

4/ warm up fast

5/long service life

6/Maintenance is simple and convenient

Application:

1/Plastic rubber industry: plastic film blowing machine, wire drawing machine, injection molding machine, granulator, rubber extruder, vulcanizing machine, cable production extruder, etc.;

2/Pharmaceutical and chemical industry: pharmaceutical infusion bags, plastic equipment production lines, liquid heating pipelines for the chemical industry;

3/Energy, food industry: heating of crude oil pipelines, food machinery, super freighters and other equipment that require electric heating;

4/Industrial high-power heating industry: machine for killing machine, reaction axe, steam generator (boiler);

5/Smelting heating industry: die casting furnace zinc alloy, aluminum alloy and other equipment;

6/Building materials industry: gas pipe production line, plastic pipe production line, PE plastic hard flat net, geonet net unit, automatic blow molding machine, PE honeycomb board production line, single and double wall corrugated pipe extrusion production line, composite air cushion film unit, PVC hard Tube, PP extrusion transparent sheet production line, extruded polystyrene foam tube, PE winding film unit;

7/ high power commercial induction cooker movement;

8/ Dry heating in printing equipment;

9/ other similar industry heating;

FAQ

Q: Is it easy for a new operator ?

A: Yes, this device easy operate and you will love it!

Q:Can I watch the heating test video before place order ?

A: Yes, you can!